The Basic Principles Of Plastic Injection Molding

The 8-Second Trick For Plastic Injection Molding

Table of ContentsLittle Known Questions About Plastic Injection Molding.Rumored Buzz on Plastic Injection MoldingPlastic Injection Molding Fundamentals ExplainedSee This Report on Plastic Injection Molding

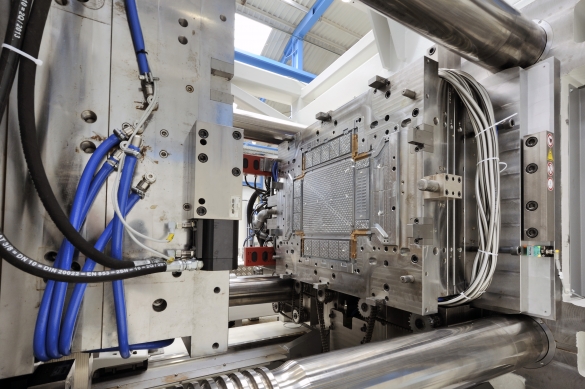

Injection moulding cycle [modify] The sequence of events during the injection mould of a plastic component is called the injection moulding cycle. The cycle starts when the mould shuts, adhered to by the injection of the polymer right into the mould cavity. When the cavity is filled up, a holding pressure is preserved to make up for material contraction.

This triggers the screw to pull back as the following shot is prepared. When the component is sufficiently trendy, the mould opens and the part is ejected.: 13 Scientific versus traditional moulding [edit] Commonly, the injection portion of the moulding process was done at one continuous stress to fill as well as load the dental caries.

As soon as the cavity is 98% complete, the device switches from rate control to pressure control, where the dental caries is "packed out" at a constant stress, where adequate rate to get to preferred pressures is called for. This lets employees manage part dimensions to within thousandths of an inch or far better. Like all industrial procedures, injection molding can generate mistaken parts, also in toys.

Getting The Plastic Injection Molding To Work

Trials are often done prior to complete production runs in an initiative to predict flaws and also figure out the appropriate specs to make use of in the injection process.: 180 When filling a new or strange mould for the very first time, where shot dimension for that mould is unknown, a technician/tool setter may carry out a dry run prior to a complete production run. plastic injection molding.

Once they accomplish this, they use a tiny quantity of holding stress and also increase holding time until entrance freeze off (solidification time) has actually happened. Gate freeze off time can be figured out by raising the hold time, and afterwards weighing the component. plastic injection molding. When the weight of the component does not transform, the gate has frozen and say goodbye to material is injected into the part.

, extremely hazardous if the component is being utilized for a safety and security vital application as the product has very little stamina when peeled as the materials can not bond. Excess product in slim layer surpassing regular part geometry Mould is over jam-packed or parting line on the device is harmed, too much shot speed/material infused, clamping force as well reduced.

Things about Plastic Injection Molding

Loading also find here quickly, not allowing the edges of the component to establish up. Mould might be out of enrollment (when the 2 fifty percents do not centre appropriately as well as part wall surfaces are not the very same thickness). The offered information is the usual understanding, Improvement: The Absence of pack (not holding) pressure (pack stress is made use of to pack out although is the component throughout the holding time).

To put it simply, as the component reduces the resin divided from itself as there was not enough resin in the cavity. The gap might happen at any kind of location or the part is not restricted by the thickness yet by the material flow as well as thermal conductivity, but it is more likely to take place at thicker areas like ribs or bosses.

Knit line/ Fuse line/ Transfer line Discoloured line where two circulation fronts satisfy Mould or material temperature levels set as well reduced (the product is cold when they fulfill, so they don't bond). Time for transition in between injection as well as transfer (to packing and also holding) is as click here to find out more well early. Turning Distorted component Cooling is as well short, material is also hot, absence of cooling around the device, incorrect water temperature levels (the parts bow inwards in the direction of the hot side of the tool) click for info Irregular diminishing in between areas of the component.

See This Report about Plastic Injection Molding

125 inch wall density is +/- 0. 008 inch (0. 2 mm).: 446 Power needs [modify] The power required for this process of injection moulding depends upon several points and varies between materials utilized. Production Processes Referral Overview mentions that the power requirements depend on "a material's certain gravity, melting factor, thermal conductivity, component dimension, and also molding price." Below is a table from page 243 of the same recommendation as formerly stated that ideal highlights the qualities relevant to the power required for the most typically utilized materials.

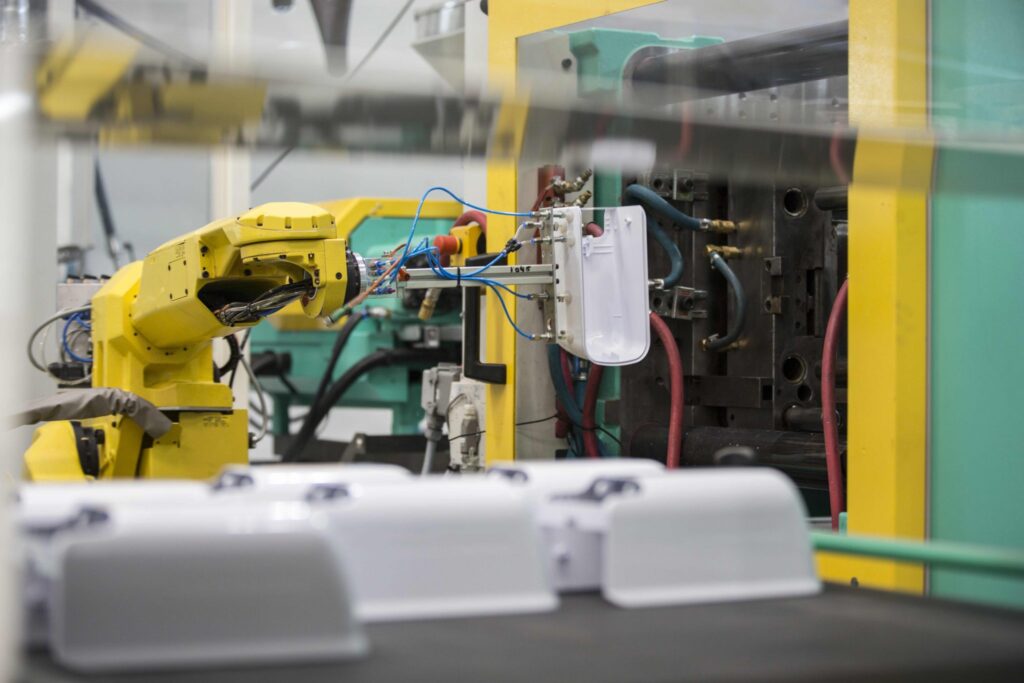

Along with installing evaluation systems on automatic devices, multiple-axis robotics can get rid of components from the mould as well as position them for further procedures. Details circumstances include removing of components from the mould immediately after the components are developed, in addition to applying machine vision systems. A robotic holds the component after the ejector pins have been extended to release the component from the mould.

Why is injection molding machine manufacturing so reliable? What is Injection Molding?

The shot molding device makes use of customized mold and mildews to fill them out according to specs, creating the same copies that can be customized in a selection of ways. What's even more, injection molding is an extremely functional process, enabling a large range of various materials as well as coatings, which makes it a prominent alternative in many sectors with completely various objectives and demands.